HOW WE PRODUCE OUR CHICKEN

At ROSE Poultry, we produce quality chicken that is Danish throughout the entire production chain. Every single step in the production is carefully optimized for quality, safety and well-being. We are quite proud of that!

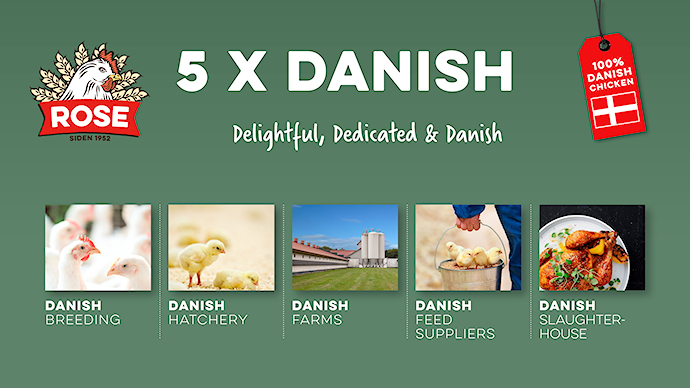

FIVE TIMES DANISH

ROSE Poultry is Danish chicken from end to end. A central starting point for our production is what we call the five DKs:

- Danish parent animals

- Danish hatchery

- Danish farms

- Danish suppliers of animal feed

- Danish slaughterhouse

You can read more about each point below.

1. Danish parent animals

The chicken comes first - at least in our story.

All our chickens come from hatching eggs laid by Danish hens. A hen lays eggs from the age of 24 weeks until she is 62 weeks old. During that period, the hen can produce around 150 hatchlings.

The eggs are collected daily, after which they are sorted according to quality and stored under controlled climatic conditions, which provide the basis for hatching healthy and viable hatchlings.

2. Danish hatchery

All our eggs are hatched in a Danish hatchery.

When the eggs arrive at the hatchery, they undergo a systematic check. After that, they are placed in incubators that ensure a constant hatching temperature as well as control of humidity and controlled air exchange around the eggs.

During the incubation process, the incubator imitates the hen's frequent rotation of the eggs. The repetitive movement ensures that the chicken has the optimal opportunity to break through and get out of the eggshell. After the first 18 days in the incubator, the eggs are transferred to a hatcher.

After 3 days in the hatcher, the hatchlings are born and then driven in specially designed trucks to the farmer where they will grow up.

3. Danish farms

The chickens are delivered to Danish chicken farms, which we have carefully selected. We work closely with our farmers, and we have a veterinarian attached to whom the farmers can engage in dialogue and ask for advice.

The farmers receive the chickens in a cleaned barn with a constant temperature of 32-34 degrees. The barn temperature is continuously lowered as the chickens grow bigger.

The chickens are inspected twice a day, where the farmer checks that the chickens are thriving.

All our chicken farms are equipped with computerized feeding and air conditioning systems that monitor the conditions of the chicken flock. Feed consumption, water intake and indoor climate are recorded continuously, and the farmer receives an immediate alarm if irregularities occur that have an impact on the well-being and welfare of the chickens.

4. Danish suppliers of animal feed

The feed for our chickens comes from approved Danish feedstuffs. This ensures a high quality of the feed, which has the nutrients the chickens need.

We usually switch between 3-4 different types of feed depending on the age of the chickens. All the feed is heat treated to ensure that the feed is salmonella free.

The feed mainly consists of wheat and soy. In addition, there are other ingredients such as oil, vitamins and minerals.

The aim is that all farmers must use 100% responsibly produced soy in the chickens feed by 2025 at the latest.

5. Danish slaughterhouse

When the chickens are ready for slaughter, we capture them, after which they are again transported in specially built trucks that ensure the right conditions for them.

The slaughtering takes place at our Danish slaughterhouse. Here, the chickens are typically slaughtered when they have reached their slaughter weight after 36 to 49 days – depending on the type of chicken.

The slaughtering itself takes place by hanging the chickens up by the legs and immediately sedating them so that they are completely unconscious before they are slaughtered. Immediately after, they are cooled down, cleaned and dismembered.

Finally, the chicken products are packed at our production facilities in Denmark and placed in cold or frozen storage.

In relation to the packaging, we work determinedly to reduce our plastic consumption and increase the recyclability of our packaging.